Navigation

- What Can You Use an Angle Grinder for?

- Can an Angle Grinder Cut Anything?

- How to Enhance the Performance of an Angle Grinder?

- Conclusion

An angle grinder is one of the most versatile power tools you can have in your garage or workshop. This handy tool can help you cut, grind, sand, polish, sharpen, and complete a wide variety of DIY and professional projects. In this comprehensive guide, we will explore everything you need to know about angle grinder uses, capabilities, and best practices.

What Can You Use an Angle Grinder for?

Angle grinders are extremely versatile tools suitable for a wide range of applications. Here are some of the most common uses and capabilities:

- Cutting metal – The rapid rotation of cutting discs easily slices through steel, iron, rebar, pipes, angle iron, sheet metal, and more. Make straight, curved, and beveled cuts in metal with ease.

- Grinding metal – Grinding and flap discs remove rust, paint, welds, and metal material very efficiently. Great for grinding welds smooth, sharpening tools, deburring metal edges, and general metal surface preparation.

- Cutting masonry – Masonry cutting wheels cut through concrete, brick, cement, tile, and stone cleanly and accurately. Make cutouts in concrete walls, trim brick surfaces, and slice tile. Use dust shrouds to contain the mess.

- Sanding and polishing – Sanding discs smooth and shape wood, plastic, metal, and painted surfaces. Polishing wheels buff metal and natural stone to a mirror-like shine. Great for restoration and finishing.

- Removing rust and paint – Wire brush wheels efficiently clean rust, paint, grime, and scale off metal, concrete, masonry, and other hard materials. Be sure to wear eye and breathing protection.

- Sharpening tools – Grinding wheels expertly sharpen a wide array of metal cutting tools. Restore sharp polished edges to lathe tools, drill bits, planer blades, knives, scissors, and more.

- Removing flooring/tile – Abrasive discs equipped with dust shrouds quickly remove tile, thinset, glue, carpet, linoleum, and other flooring materials. Makes floor prep much easier.

- Cutting tile – Tile cutting discs accurately cut curves, notches, and openings in ceramic, porcelain, and natural stone tile. Cuts much faster than a tile saw.

- Cleaning grout – Special grout removal discs clean out old discolored grout between tiles. Prepares the way for re-grouting.

While angle grinders are primarily used for cutting, grinding, and sharpening tasks, there are some surprising uses of an angle grinder are:

- Engrave designs into stone/concrete – With diamond engraving discs, you can etch customized lettering, images, and patterns into stone countertops, concrete walls, pavers, tombstones, and other masonry. Create unique personalized decor.

- Sculpt and shape wood – Grinding discs efficiently sculpt and contour wood into artistic shapes, patterns, and functional items. Make customized furniture accents, bowls, decor, outdoor wood art, and more.

- Trench and slice tree roots – Cut through troublesome surface tree roots up to 3-4 inches thick with a cutting wheel. Trench alongside the roots, cut across, and remove segmented root sections.

- Detail tight vehicle areas – Special detail angle grinders allow you to polish, buff, and apply compounds in tight crevices, curves, and edges that are difficult to reach. Target wheel wells, trim, emblems, etc.

- Fabricate custom metal tools – Cut, grind, and shape steel to create specialized tools like chisels, shears, scraping tools, edgers, fettlins, and more. Make exactly what you need.

- Cut and smooth plastics – Carefully cut and grind plastics like acrylic sheets, PVC pipe, fiberglass, polycarbonate, HDPE, acetals and more using fine-grit sanding discs.

Angle grinders tackle so many different jobs thanks to the wide variety of abrasive accessories available. Cutting, grinding, sharpening, polishing, cleaning – an angle grinder can do it all!

Can an Angle Grinder Cut Anything?

Angle grinders are remarkably versatile for cutting, but there are some limitations to what they can handle.

Materials an angle grinder can cut:

- All standard metals – This includes steel, iron, rebar, sheet metal, pipes, tubes, angle iron, etc. Use proper cutting discs.

- Tile, concrete, cement, cinder blocks, bricks – Masonry cutting wheels make fast work of most building materials. Maintain blade integrity.

- Fiberglass, acrylic sheets, plastics – Difficult to cut cleanly but can be done with the right discs. Beware of melting.

- Wood – Relatively easy for small cuts but can burn and bind the blade. Don’t force cuts.

Materials not suitable for angle grinder cutting:

- Glass – The blade may shatter the glass. A glass-cutting tool is safer and more effective.

- Very thick/large metal objects – Size and hardness can exceed cutting capacity. Choose a more powerful tool.

- Highly abrasive metals – Materials like stainless steel require specialized cutting discs to avoid rapid wear.

- Very hard masonry – An angle grinder struggles with granite, engineered stone, and some reinforced materials.

Proper blade selection is crucial for optimal cutting. Thin reinforced wheels for metal, diamond blades for masonry and tile, and finer grit wheels for plastic and wood.

The thickness and hardness of the material greatly impact cutability. An angle grinder will easily cut 1/8″ steel but may bind and stall on a 1″ steel beam. Check your grinder’s power rating and match the cutting task accordingly.

For tougher jobs, consider alternative tools like a circular saw, reciprocating saw, or tile saw specifically designed for that material. Within reasonable size limits though, an angle grinder equipped with the right blade can cut through virtually anything.

How to Enhance the Performance of an Angle Grinder?

To get the utmost capabilities and value from your angle grinder, there are several important tips to keep in mind:

- Choose the optimal size grinder – Smaller 4-1/2″ angle grinders work well for detail work, tight spots, and simple tasks. Larger 9″ grinders are heavier but have more power for sustained grinding and cutting of substantial materials. Select the minimum size necessary for your purposes. Too much power can be unsafe for delicate work.

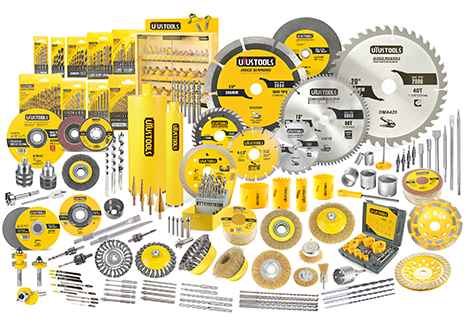

- Purchase quality grinding and cutting discs – The quality of the discs directly impacts performance. Low-cost discs tend to wear out faster, overheat, and even shatter dangerously. Invest in premium abrasive discs from trusted brands. They will cut cleaner and last exponentially longer.

- Avoid overloading the angle grinder – Don’t push too hard or take too much material off in one pass. This can bog down the motor, overheat the tool, or damage the disc. Make gradual, repeated shallow passes for optimal grinding and cutting efficiency. Let the tool work at its designed speed.

- Install an auxiliary handle or paddle switch – Supplementing the standard slide switch with an adjustable paddle trigger gives you enhanced comfort and control. The extra leverage helps counter torque. Aux handles also let you grip with two hands for straight steady cuts.

- Use the included safety guard – The wheel guard that comes standard with quality angle grinders protects you from flying sparks and debris. Never remove it. If it’s damaged, replace it immediately. The guard also makes it safer to rest the angle grinder against your work.

- Secure your workpiece properly – For straight cuts, securely clamp down the metal, tile, or other material you are cutting. This frees up both hands to control and guide the angle grinder properly. Never try to cut handheld workpieces.

- Employ proper cutting/grinding techniques – There are optimal techniques for different tasks. Keep the cutting disc perpendicular to the work when cutting. Angle it slightly when beveling edges. Hold grinding discs flat to the surface to avoid gouging. Let the abrasive disc do the work efficiently and safely.

- Use appropriate safety gear – At a minimum, always employ eye and breathing protection when using an angle grinder. Sturdy gloves provide an extra layer of defense. Make sure to protect yourself from debris, sparks, and loud noise.

Optimizing technique, using quality consumables, and equipping safeguards allows you to enhance the usefulness of an angle grinder. Matching the right angle grinder size to each job also boosts performance. With practice and prudence, an angle grinder can take on just about any grinding, cutting, or sharpening task.

Conclusion

With an understanding of angle grinder capabilities and uses, you can take full advantage of this essential power tool. Always select the right disc for the job and implement safety best practices. Your angle grinder will quickly become your go-to tool for big and small tasks.

We hope this overview gives you confidence in using an angle grinder to its full potential. The uses are almost endless with the right attachments and techniques. So put your grinder to work: cutting, grinding, sharpening, and polishing!