Navigation

- Things to Consider When Choosing the Right Angle Grinder Suppliers?

- Who Is the Best Angle Grinder Supplier?

- Final Words

Choosing the right angle grinder supplier is a crucial decision that can significantly impact your business operations and end product quality. With the right supplier, you can ensure efficiency, cost-effectiveness, and high performance in your grinding, cutting, and polishing work. This article will guide you through the key factors to evaluate when selecting suppliers for your industrial or construction business and help you find the best angle grinder supplier-UYUSTOOLS

Things to Consider When Choosing the Right Angle Grinder Suppliers?

1. Assessing Supplier Reliability

Vetting suppliers thoroughly is crucial for securing reliable delivery of top-quality angle grinders. Start by examining their reputation through customer reviews, testimonials, case studies, and direct client references. Look for suppliers with a lengthy history and many long-term clients providing glowing feedback. This indicates a dedication to customer retention building trust, and mutually beneficial relationships.

Also investigate the financial health of suppliers through careful analysis of recent financial statements, credit reports, and press releases. Look for steady revenue/profit growth over time without erratic swings or losses. Conservative finances with wise fiscal management reduce the risk of abrupt supplier closures or service interruptions down the road.

Request evidence of quality management certifications and compliance audits as well. Adherence to ISO standards and safety regulations across all business processes demonstrates a commitment to consistency and excellence you can rely on.

2. Quality of Products

The durability, performance, and safety of angle grinders have major impacts on workflow efficiency, final product quality, and worker protection. Thoroughly vet manufacturing processes used by having in-depth discussions with engineers, touring facilities, and rigorously testing sample products.

Verify adherence to ISO 9001 and other globally recognized quality standards through third-party audits and certifications. This level of quality control minimizes defects and variability. Inspect material sourcing – premium alloys and insulated handles indicate attention to product excellence and worker safety.

Test sample grinders under real working conditions – intensive, continuous operation over an extended period. Listen for abnormalities and watch for signs of excess wear, overheating, or subpar performance. The ideal supplier will confidently demonstrate grinders withstand punishing work environments without safety risks or premature failure.

3. Cost-Effectiveness

Achieving optimal value requires a nuanced approach beyond just seeking the lowest sticker price. Bargain pricing often indicates cut corners in materials, quality control, or ethical labor practices.

Ask about volume discounts for large orders, but investigate if manufacturing quality remains consistent at scale. Suppliers should demonstrate how cost-savings are responsibly achieved through efficiencies, not skimping on worker protections or product durability.

Also consider after-purchase costs like replacement parts, repairs, and maintenance. Suppliers with reasonable service rates and readily available spare parts provide better long-term savings.

Evaluate energy efficiency as well. Advanced grinders with improved power management save substantially on electricity over time. The modest upfront premium is recouped through years of utility savings.

4. Service and Support

The technical expertise and post-purchase services a supplier provides are critical for maximizing uptime and workforce productivity.

Ask about repair turnaround time – suppliers with in-house technicians and local service centers enable fast, convenient fixes to get grinders running again promptly. Multi-year maintenance contracts can be economical for planning purposes.

Ongoing training is also valuable. Operators well-versed in equipment handling, accessories selection, and safety protocols work more skillfully, safely, and autonomously. Troubleshooting assistance speeds diagnosis and problem resolution.

Product seminars and demos help workers understand new models and features. Safety briefings reinforce good practices and hazard awareness. Knowledgeable, attentive support unlocks a grinder’s full potential.

5. Delivery Capabilities

Efficient order processing and prompt delivery are imperative for smooth business operations. Evaluate suppliers’ ordering procedures – simple placement through multiple channels indicates customer focus. Seek order confirmations with estimated ship dates and tracking numbers for visibility.

Inquire about guaranteed delivery lead times. Suppliers should regularly meet on-time delivery targets, with contingency plans to rapidly recover from any delays or disruptions. Just-in-time practices reduce inventory carrying costs.

Ask about inventory and warehouse management as well. Robust forecasting, stock monitoring, and replenishment procedures prevent shortages so orders can ship immediately. Insufficient systems lead to stock-outs, backorders, and stalled productivity.

6. Product Range and Accessories

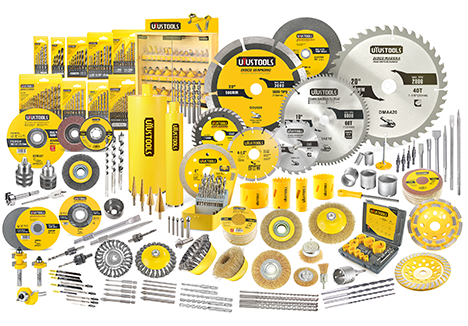

Seek suppliers with diverse angle grinder models catering to all industrial and construction applications. A spectrum of sizes, motor power, handles, and wheel types adds versatility. Niche products for specific materials like tile, masonry, and metal demonstrate deep capabilities.

Convenient access to replacement parts and accessories also boosts efficiency. Evaluate the breadth and depth of inventory for consumables like discs, flanges, guards, and handles. A wide variety of grits and abrasive discs prevents improper matches that damage workpieces.

Well-stocked local warehouses get accessories to job sites rapidly. Insist on genuine OEM parts manufactured to exacting specifications for proper fit and function. Avoid suppliers peddling inferior knock-offs.

Who Is the Best Angle Grinder Supplier?

With an unwavering commitment to providing reliable, durable tools, UYUSTOOLS has firmly established itself as a leading worldwide supplier of top-tier angle grinders.

Founded in 2001 in China, UYUSTOOLS has spent over two decades building an esteemed brand that delivers complete solutions for construction, maintenance, and industrial applications. Their grinders are now exported to over 70 countries across 6 continents, engineered to comply with rigorous international standards for safety, quality, and performance.

The expansive UYUSTOOLS angle grinder lineup offers unparalleled versatility to address diverse business and commercial needs. For instance, compact and ergonomic models like the UY-AMA03-115 provide excellent maneuverability in tight spaces, while heavy-duty grinders like the UY-AMA230 deliver unmatched power for tackling the most demanding industrial tasks. Advanced features such as dust-resistant motors and improved cooling optimize efficiency, longevity, and user comfort.

UYUSTOOLS focuses on delivering outstanding wholesale value, with very competitive pricing and bulk order capability ideal for fully equipping workforces with reliable, long-lasting grinders. Their customer service also shines, offering comprehensive guidance from knowledgeable staff to help select the right models and accessories tailored to your specific applications.

With a vast range of high-performing angle grinders backed by attentive customer support, UYUSTOOLS has firmly established itself as the premier global supplier for finding the perfect grinder to take your projects to the next level. Browse their power tools selection to discover an unbeatable range of durable, precision grinders purpose-engineered to help you excel.

Final Words

Choosing the optimal angle grinder supplier requires thorough analysis across a range of criteria. By evaluating reliability, product quality, cost-effectiveness, services, delivery, and product line, you can determine the best fit for your industrial or construction operations.

Put your trust in UYUSTOOLS which has proved its commitment to consistent quality, and responsiveness to your needs, and enhance your business performance. With the right supplier partnership with UYUSTOOLS, your workers will gain efficiency and you’ll avoid costly downtime.